Client Profile

Property and underground storage tank (UST) owner at an active retail fueling station and convenience store located on a one-quarter acre parcel.

Project Profile

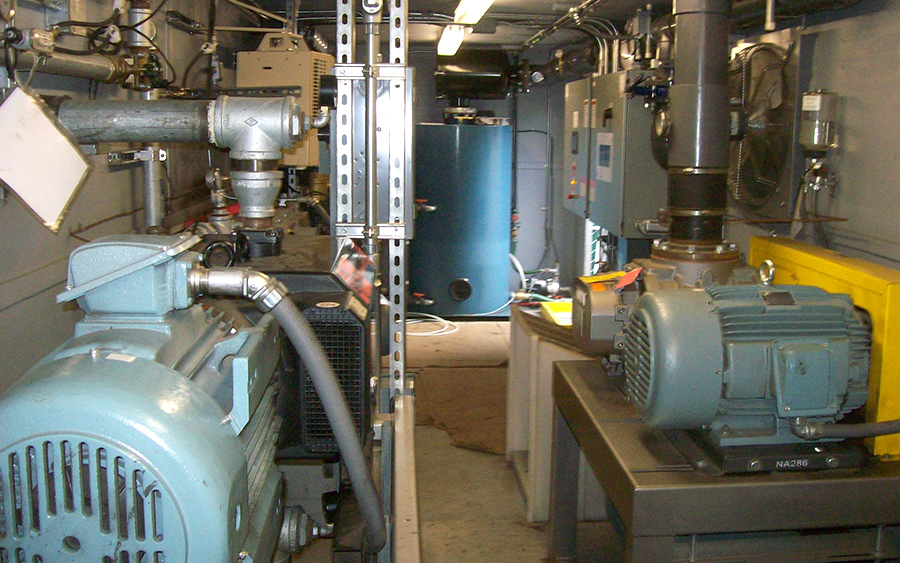

Based on site characterization results, soil and groundwater impacted with unleaded gasoline constituents were located on-site and off-site. Impacted groundwater had migrated off-site beneath a roadway and an off-site parcel and was likely discharging to the adjacent river. Light non-aqueous phase liquid (LNAPL) was also present on-site at an approximate thickness of 0.5 feet. An aggressive soil and groundwater remediation strategy to attain the applicable PADEP Used Aquifer Residential Statewide Health Standards (UARSHS) Medium-Specific Concentrations (MSC) involved the operation of a combined Air Sparge (AS) / Soil Vapor Extraction (SVE) / Vapor Enhanced Groundwater Extraction (VEGE) remediation system. The off-site strategy was monitored natural attenuation (MNA), which is a passive remediation method that relies on natural attenuation mechanisms to degrade and reduce concentrations of constituents of concern in groundwater. AS technology was particularly applicable considering the high porosity of the site fill and geology. VEGE technology was applicable based on the depth to water ranging from 20 to 25 feet below ground surface.

Project Summary

The active AS/SVE/VEGE remediation system operated on-site for approximately two years to successfully remediate soil and groundwater. In-situ AS with associated SVE is a remedial method of direct aeration/in-situ stripping combined with bioremediation stimulation. In-situ air sparging required an air injection system and a vapor extraction system. Air was injected into the groundwater through a series of injection wells. As the injected air rose in the water table, hydrocarbons were stripped from the groundwater and capillary fringe. Vapors were extracted by the system via a blower. The blower intake produced a vacuum to remove soil vapor from recovery wells. Groundwater was removed via submersible pumps. Volatilization of hydrocarbons was increased with vapor movement and bioremediation of hydrocarbons was also increased with the influx of additional oxygen. Air sparge was performed via six air sparge wells; VEGE and SVE were performed at three recovery wells. In total, the remediation system extracted, treated, and discharged approximately 1,968,247 gallons of groundwater under a National Pollutant Discharge Elimination System (NPDES) Permit.

Attainment of the SHS MSC in soil was demonstrated via PADEP’s Systematic Random Soil Sampling (SRSS) Protocol approximately two months after the AS/SVE/VEGE remediation system was deactivated. SRSS was completed at a depth interval of 12 to 18 feet below ground surface on-site and off-site to verify that post-remedial unsaturated soil attained the SHS. The SRSS investigation involved the advancement of 12 soil borings using Geoprobe® direct push technology and the collection of one soil sample per boring for laboratory analysis. All soil analytical results were below their respective UARSHS MSCs for the regulated unleaded gasoline parameters.

Attainment of UARSHS MSCs in groundwater was demonstrated via eight consecutive post-remediation quarterly groundwater monitoring events.

Project Results

Site closure with a Relief of Liability via a PADEP-approved Remedial Action Completion Report was achieved within less than five years of initiating AS/SVE/VEGE remediation activities. Based on site characterization and SRSS analytical (soil) results and eight consecutive quarters of post-remedial groundwater analytical data from all 10 monitoring wells (including the five point of compliance wells), soil and groundwater attainment of the UARSHS MSCs for the unleaded gasoline parameters of benzene, toluene, ethylbenzene, xylenes, methyl tertiary-butyl ether (MTBE), cumene, naphthalene, 1,2,4-trimethylbenzene (TMB), and 1,3,5-TMB was demonstrated.